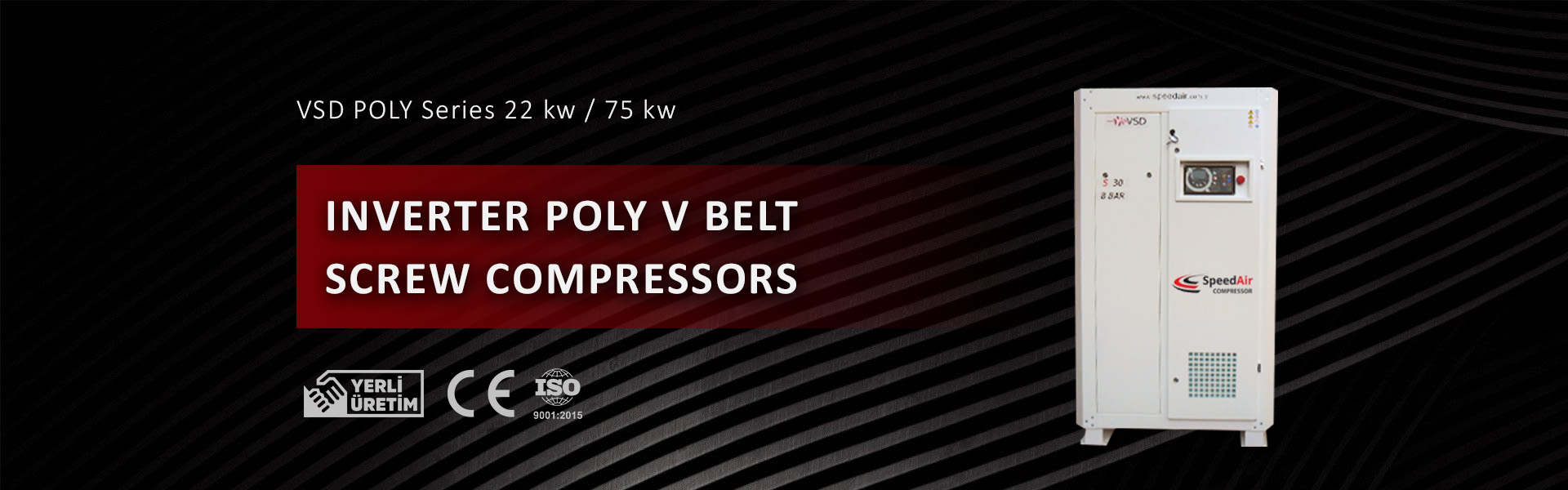

Screw Compressor

SpeedAir Industrial screw compressors are highly efficient and durable machines that produce compressed air by compressing air or gases. The term "screw" refers to the mechanism that performs the air compression process of the compressor, which is made up of two rotating screws (rotors). These types of compressors are used intensively, especially in industrial and industrial areas.

Features:

Working Principle: Industrial screw compressors achieve high pressure by compressing air while two helical screw rotors rotate in close proximity to each other. As the air passes through the rotors, its volume decreases and its pressure increases.

Efficiency: They provide high efficiency operation because instead of constantly compressing air, the air is compressed more homogeneously thanks to the gaps between the rotors. This reduces energy consumption.

Low Noise and Vibration: They offer lower noise and vibration levels compared to other types of compressors. This makes them ideal for workplaces that are particularly sensitive to noise.

Durability: Screw compressors are designed for long-term use and can operate efficiently for many years with regular maintenance.

Areas of Use:

Factory and manufacturing processes: Provides air supply for air-powered machines and equipment.

Automotive industry: Used for air vehicles, test machines or production lines.

Chemical and pharmaceutical industry: Used in systems operating with air pressure, in sectors requiring clean and dry air.

Mining and construction sectors: Preferred in grinding and drilling machines that require high-pressure air.

Industrial screw compressors are widely preferred compressors in the industrial world with their low maintenance requirements, long life and high performance.

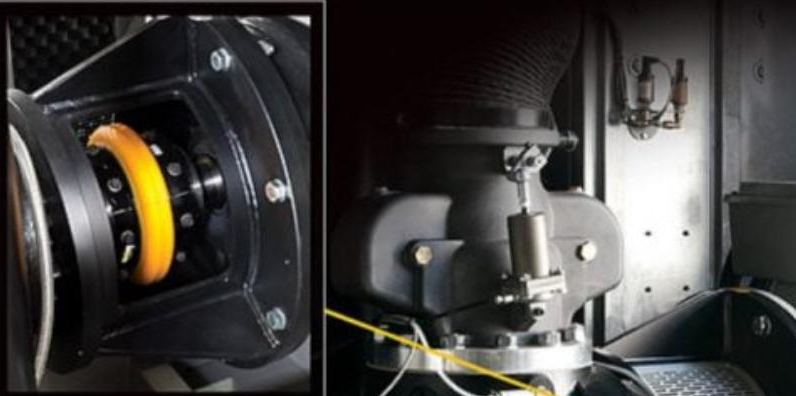

Laser Cutting Compressors

16 Bar Laser Cutting Compressors

Laser cutting machines work with gases like oxygen or nitrogen to cut materials with high precision. To ensure efficient operation, these machines require high-pressure compressors. 16 bar laser cutting compressors are especially important for cutting large and thick metal sheets.

Advantages:

- High Pressure: 16 bar pressure increases cutting speed and results in cleaner, smoother material surfaces.

- Energy Efficiency: Modern 16 bar compressors provide high efficiency with low energy consumption.

- Air Quality: Clean, dry air ensures proper laser beam focus and improves cutting quality.

- Durability and Reliability: High-quality compressors operate safely and efficiently over long periods.

In conclusion, 16 bar laser cutting compressors play a critical role in speeding up the cutting process and ensuring high-quality, efficient production.

Review

Compressed Air Dryers

The Key to High Performance

Compressed air is widely used in industrial applications, but the moisture in the air can cause corrosion, efficiency loss, and equipment failures. Compressed air dryers remove moisture, preventing these issues and ensuring the system operates efficiently.

A high-performance compressed air dryer should have low pressure drop, energy efficiency, durability, and easy maintenance features. These dryers are crucial in sensitive industries such as automotive, food, pharmaceuticals, and electronics, where moisture-related quality loss and malfunctions are avoided.

In conclusion, compressed air dryers are essential systems that improve industrial efficiency, extend equipment life, and reduce maintenance costs.

ReviewProducts

Projects

Completed Projects

We Combine Strength with Durability!

We are proud to offer compressor solutions, each designed for specific needs and projects. Our completed projects are a reflection of our customer satisfaction-oriented service approach. Our compressors, which we produce with high technology and durable materials, provide efficiency and reliability to our business partners in different sectors. We have successfully completed our projects that support business continuity by providing on-time delivery and quality installation service. We will continue to produce industrial and commercial solutions in the future and respond to customer demands in the best way possible.

VSD DA Energy Saving Compressor

We have completed the project of 2 units of 55 kW VSD DA energy saving compressors. SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertook.

VSD Coupled Energy Saving Compressor

We have completed the delivery of the 90 kW VSD Coupled Energy Saving Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertake.

VSD Coupled Screw Compressor

We have completed the delivery of the 55 kW VSD Coupled Energy Saving Screw Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertake.

VSD DA Economical Compressor

We have completed the delivery of the 90 kW VSD DA Energy Saving Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertake.

VSD DA 250 kW Screw Compressor

We have completed the delivery of the 250 kW VSD DA Energy Saving Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertake.

VSD DA 37 kW Screw Compressor

We have completed the delivery of the 37 kW VSD DA Energy Saving Screw Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertake.

VSD DA 22 kW Screw Compressor

We have completed the delivery of the 22 kW VSD DA Energy Saving Screw Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we undertake.

15/20 Hp Fixed Speed Screw Compressor

We have completed the delivery of the 15/20 Hp Fixed Speed Screw Compressor. As SpeedAir Compressor, we have completed all the sales, installation and maintenance services we have undertaken.

Referances